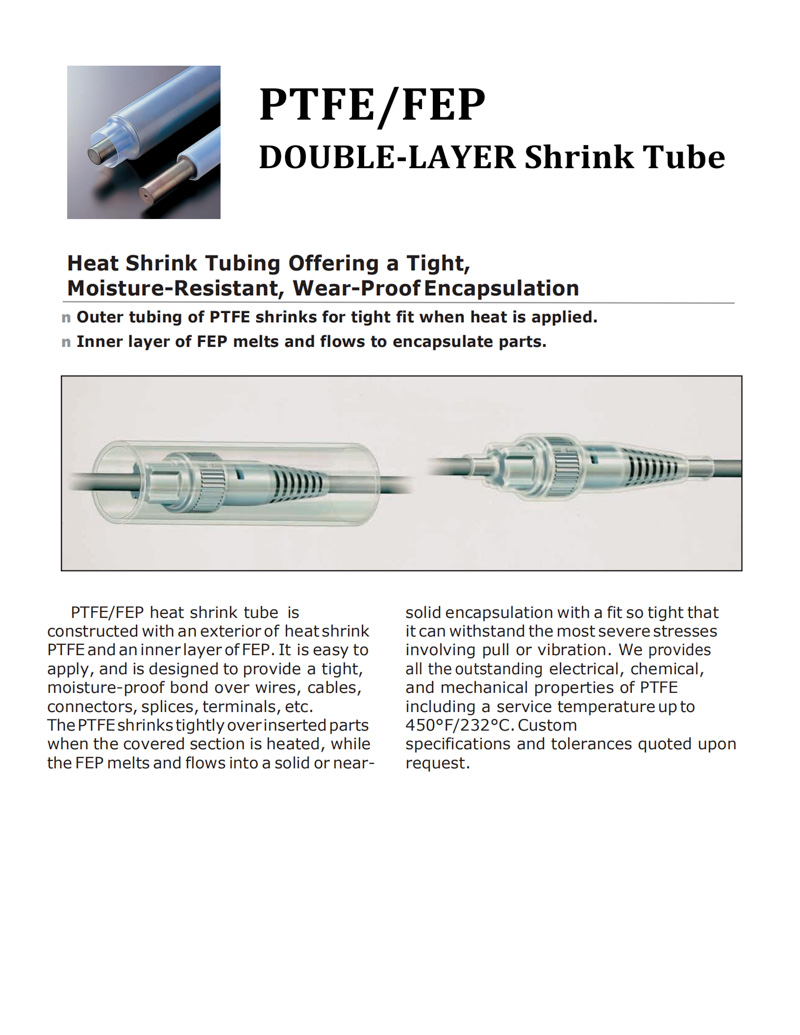

Product Description

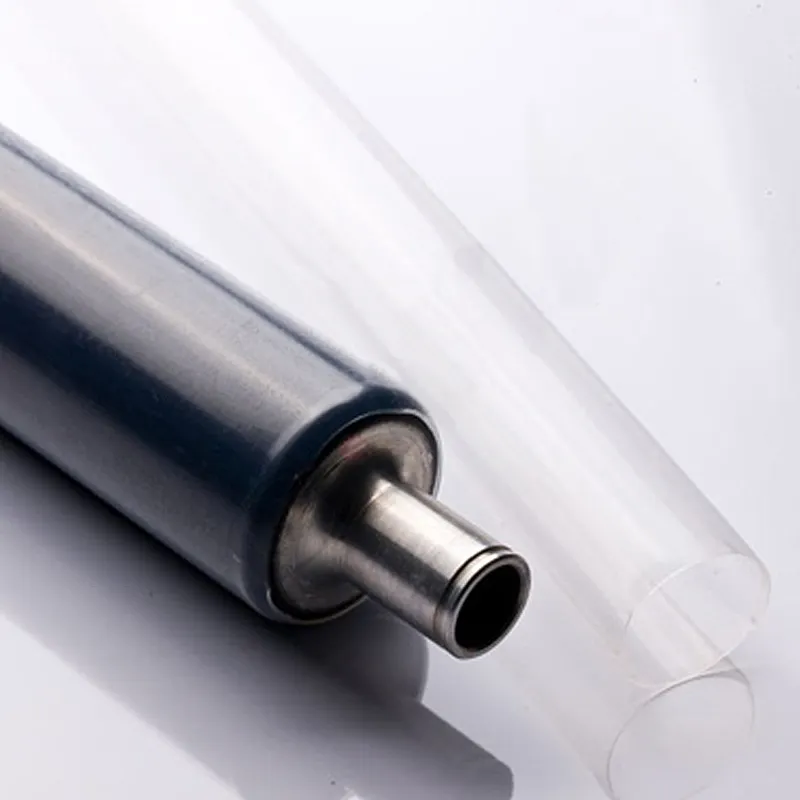

The properties of FEP copolymer are similar to those of PTEE, but its heat resistance is slightly lower, and it can workat- 85℃ + 205℃ for a long time, andat - 200℃ +300℃ for a short time ; it has high impact strength,creep resistance, and low temperatureflexibility, which is better than PTEE ; its crystallinity is different with the heat treatment temperature, and its molding processability is good ; it is non-toxic, non sticky, electrical insulation, wear resistance and chemical stability are better than PTEE It has excellent high and low temperature resistance, oil resistance and chemical reagent resistance. It is mainly used for insulation sheath of mechanical equipment, medical equipment,communication equipment, chemical industry, automobile industry, main insulation of motor rotor, water treatment, coating of roller barrel in oil field.

Product features

Corrosion resistance : only fluorine and alkali metals play a role in it at high temperature, and have no effect on all other inorganic organic acids, bases and esters.

High and low temperature resistance :- 85℃to 200 ℃ high temperature

Low water absorption : low water absorption < 0.01%

Incombustibility : no combustion in the air (oxygen index> 95 vo.%)

Non toxic: physiological inertia

High transparency: low refractive index in the plastic

Non stick: hydrophobic, oil repellent

Electrical property : high insulation : the dielectric constant viscosity of 60hz- 60mhz at high and low temperature is 2.1.Even if the surface is damaged by diving, there will be no conductive track.Volume resistance > 1018 Q m, surface resistance > 1013 Q, arc resistance 》165S No leakage of electricity

Low friction: dynamic friction coefficient 0.2-0.3

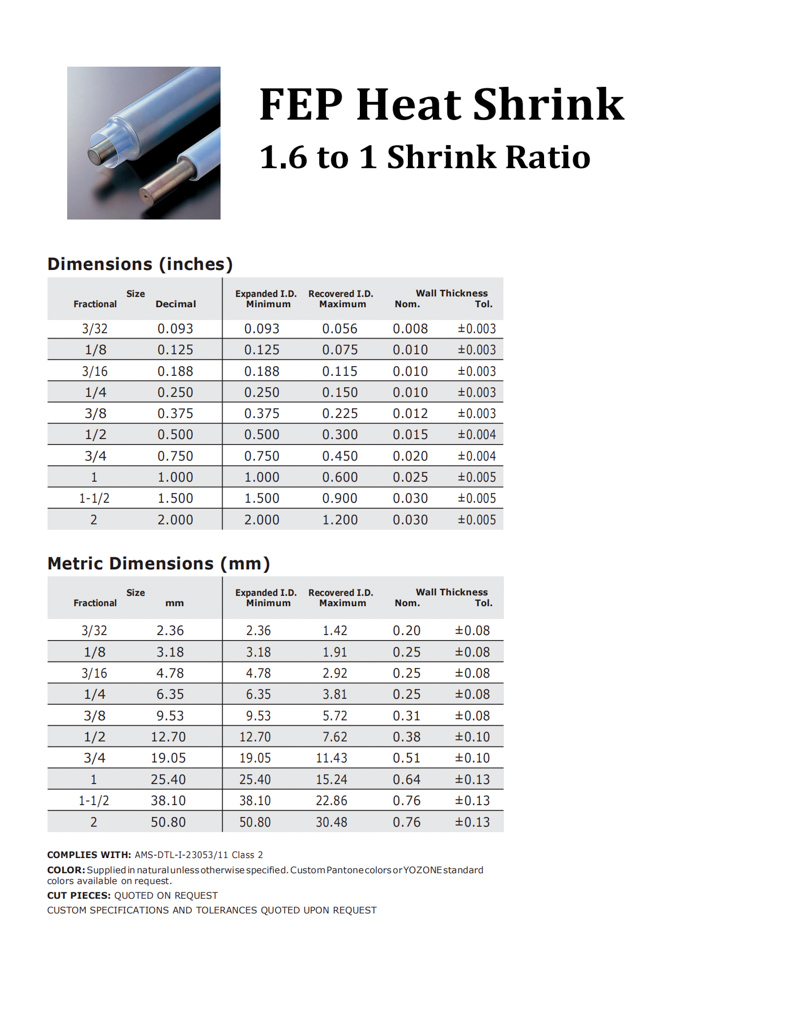

Machinability : easy for secondary processing, self sealing, self welding,flanging and coil tube. Heat shrinkage ratio : 1.6 :1

Heat shrinkage temperature : 120℃~ 200℃

Technical index

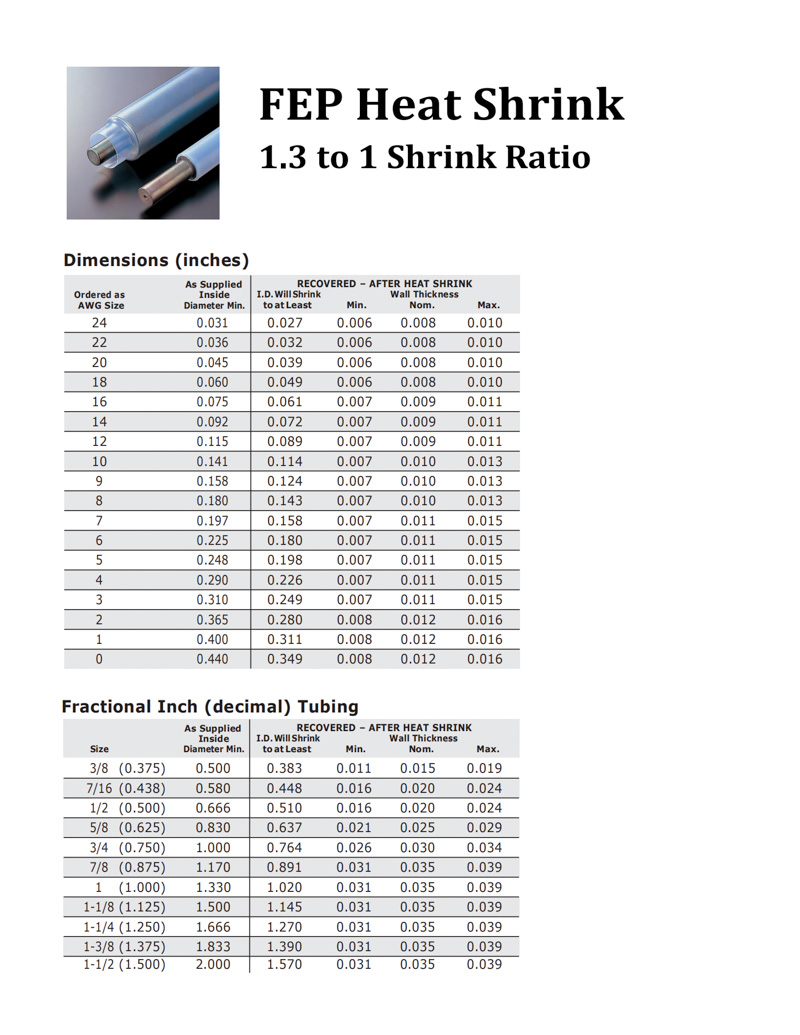

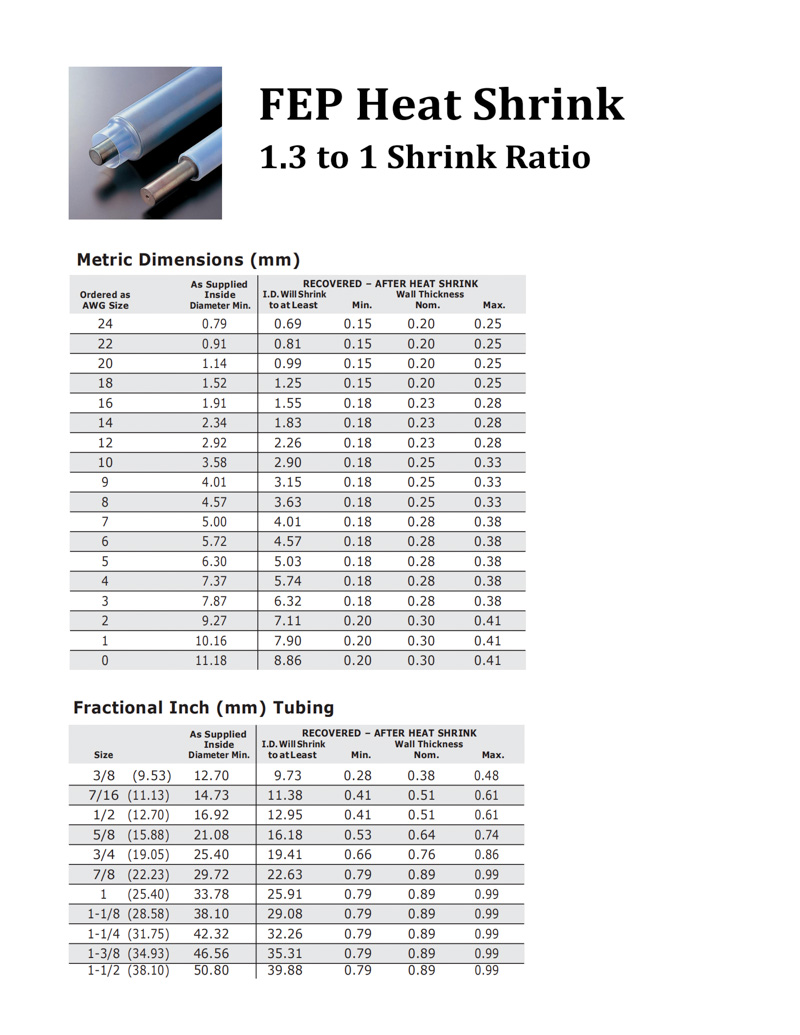

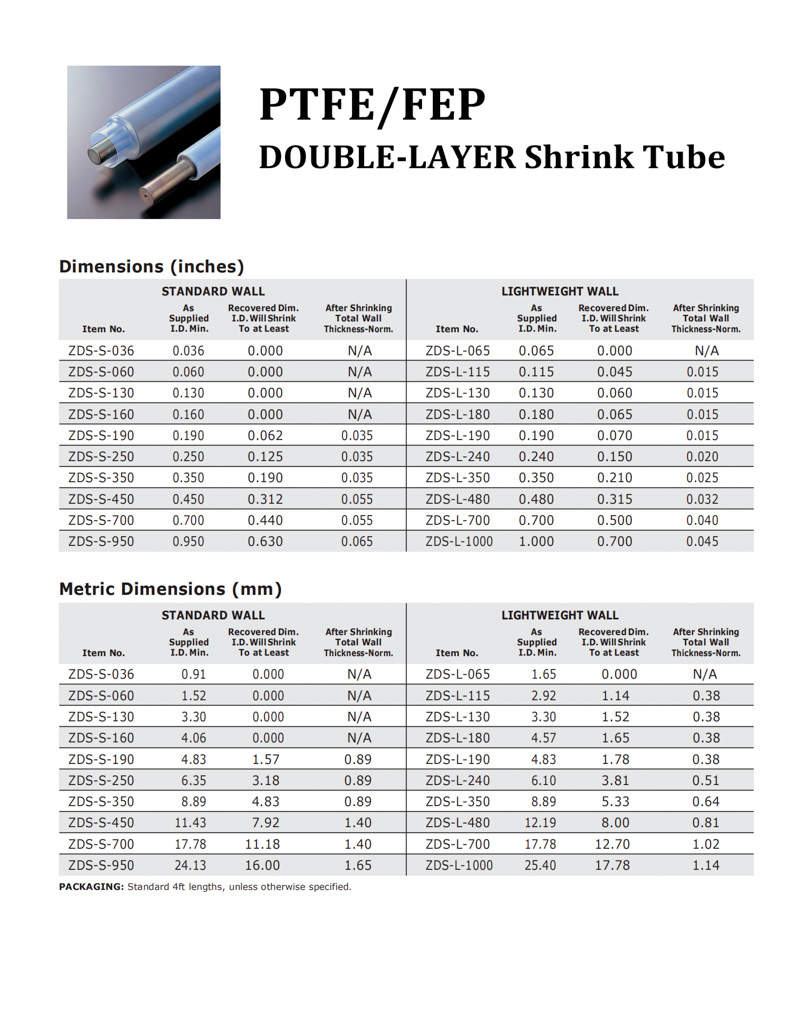

Our FEP heat shrink tubes are crafted from pure high-molecular FEP material (Fluorinated Ethylene Propylene), ensuring exceptional stretch-ability and durability.

We offer a range of 23 standard dimensions for our products, featuring diameters spanning from 0.68 mm to 200 mm. Our packaging options are customized to meet the specific requests of our customers. Additionally, we have the capability to produce these products in various colors upon request.

|

FEP Standard Heat Shrink Tube (mm) |

|||

|

max ID |

min ID |

Wall thick at min |

Wall tolerance(+/- mm) |

|

0.78 |

0,68 |

0,20 |

0.03~0.05 |

|

0.91 |

0,81 |

0,20 |

0.03~0.05 |

|

1.14 |

0,99 |

0,20 |

0.03~0.05 |

|

1.52 |

1,24 |

0,20 |

0.03~0.05 |

|

1.60 |

1.10 |

0.25 |

0.03~0.05 |

|

1.90 |

1,55 |

0,23 |

0.03~0.05 |

|

2.00 |

1.50 |

0.30 |

0.03~0.05 |

|

2.50 |

1.90 |

0.20 |

0.03~0.05 |

|

3.60 |

2.70 |

0.20 |

0.03~0.05 |

|

4.20 |

3.00 |

0.50 |

0.03~0.05 |

|

4.80 |

3.60 |

0.27 |

0.03~0.05 |

|

5.00 |

4,00 |

0,28 |

0.03~0.05 |

|

5.70 |

4,57 |

0,28 |

0.03~0.05 |

|

6.20 |

4.60 |

0.30 |

0.03~0.05 |

|

7.36 |

5,75 |

0,28 |

0.03~0.05 |

|

7.85 |

6,33 |

0,28 |

0.03~0.05 |

|

8.00 |

6.00 |

0.30 |

0.03~0.05 |

|

9.50 |

7.00 |

0.50 |

0.03~0.05 |

|

12.00 |

9.00 |

0.50 |

0.03~0.05 |

|

13.50 |

10.00 |

0.50 |

0.03~0.05 |

|

15.00 |

11.00 |

0.50 |

0.03~0.05 |

|

18.00 |

13.00 |

0.50 |

0.03~0.05 |

|

19.00 |

14.00 |

0.50 |

0.03~0.05 |

|

22.00 |

16.00 |

0.50 |

0.03~0.05 |

|

25.00 |

19.00 |

0.50 |

0.03~0.05 |

|

31.00 |

23.00 |

0.50 |

0.03~0.05 |

|

36.00 |

27.00 |

0.50 |

0.03~0.05 |

|

43.00 |

32.00 |

0.50 |

0.03~0.05 |

|

54.00 |

40.00 |

0.50 |

0.03~0.05 |

|

62.00 |

46.00 |

0.50 |

0.03~0.05 |

|

76.00 |

56.00 |

0.50 |

0.03~0.05 |

|

85.00 |

65.00 |

0.50 |

0.03~0.05 |

|

96.00 |

80.00 |

0.50 |

0.03~0.05 |

|

105.00 |

95.00 |

0.50 |

0.03~0.05 |

|

110.00 |

95.00 |

0.50 |

0.03~0.05 |

|

115.00 |

95.00 |

0.50 |

0.03~0.05 |

|

130.00 |

107.00 |

1.50 |

0.03~0.05 |

|

150.00 |

113.00 |

0.70 |

0.03~0.05 |

|

FEP light heat shrink tube (mm) |

|||

|

max ID |

min ID |

wall thick at min |

Wall tolerance(+/- mm) |

|

1.80 |

1.30 |

0.15 |

0.03~0.05 |

|

2.60 |

2.00 |

0.20 |

0.03~0.05 |

|

3.40 |

2.60 |

0.10 |

0.03~0.05 |

|

5.00 |

3.50 |

0.10 |

0.03~0.05 |

|

5.10 |

3.80 |

0.25 |

0.03~0.05 |

|

7.40 |

5.50 |

0.25 |

0.03~0.05 |

|

10.20 |

7.50 |

0.25 |

0.03~0.05 |

|

12.80 |

9.50 |

0.25 |

0.03~0.05 |

|

14.00 |

11.00 |

0.10 |

0.03~0.05 |

|

14.50 |

12.00 |

0.10 |

0.03~0.05 |

|

18.00 |

13.00 |

0.25 |

0.03~0.05 |

|

22.00 |

16.00 |

0.25 |

0.03~0.05 |

|

25.00 |

19.00 |

0.25 |

0.03~0.05 |

|

31.00 |

23.00 |

0.25 |

0.03~0.05 |

|

36.00 |

27.00 |

0.25 |

0.03~0.05 |

|

43.00 |

32.00 |

0.25 |

0.03~0.05 |

|

53.00 |

39.00 |

0.25 |

0.03~0.05 |

|

62.00 |

46.00 |

0.25 |

0.03~0.05 |